In the fields of aerospace, precision manufacturing, and high-end equipment inspection and maintenance, the demand for intuitive inspection of microscopic and concealed spaces is becoming increasingly urgent. Ultra-fine industrial endoscopes (typically referring to those with an outer diameter of less than 1 mm) are key tools for achieving "non-destructive testing." Their technological development directly impacts the precision inspection capabilities of numerous industries. However, reducing the endoscope tube diameter to the sub-millimeter level (e.g., Φ0.48 mm) while maintaining inspection reliability is a cutting-edge challenge that integrates multiple disciplines. Currently, fiber optic endoscopes can achieve this scale. This article aims to analyze the core technical difficulties of ultra-fine industrial endoscopes and elaborate on their broad application value.

I. What Are the Core Technical Difficulties?

The development of ultra-fine industrial endoscopes (using fiber optic endoscopes as an example) is by no means a simple miniaturization process. Its technical barriers mainly lie in the following three interrelated aspects:

1. Integration and Material Breakthroughs for Ultra-Fine Probes

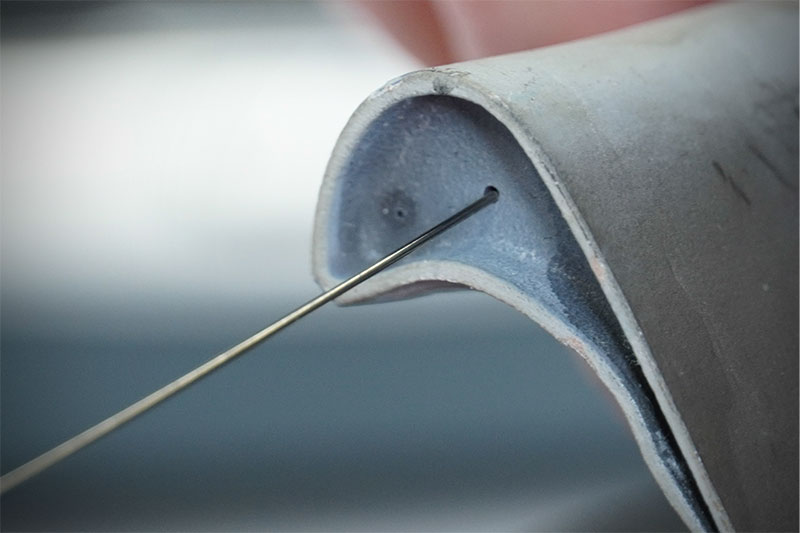

This is the most fundamental physical constraint. Within a probe tube with a diameter of less than 0.5 mm, two independent systems—the image transmission fiber bundle and the light guide fiber bundle—must be integrated in parallel. The image transmission bundle consists of tens of thousands of orderly arranged micron-sized optical fibers; the precision of this arrangement directly determines the image resolution. The light guide bundle must efficiently and uniformly transmit illumination light. The challenge lies in overcoming material limitations: integrating more optical fibers while maintaining the same probe diameter, or making the probe smaller while keeping the pixel count constant.

2. Micro-Cavity Ambient Illumination and Image Transmission

"Fineness" cannot come at the expense of "clarity." Achieving high-definition imaging within an extremely fine probe tube faces multiple optical challenges:

Insufficient Light Intake: The smaller the front-end diameter of the probe, the weaker the captured light signal.

Aberration Control: Each optical fiber transmits one pixel; maintaining the pixel count requires keeping the number of fibers constant, complicating optical design in a tiny space.

Signal Fidelity: After the image is pixelated and transmitted through tens of thousands of fibers, the backend system must accurately reconstruct it, suppressing noise and artifacts.

3. System Integration and Human-Centered Design

An excellent ultra-fine endoscope must be a reliable industrial instrument. This requires:

A Miniature Probe: The probe must be extremely fine yet possess both toughness and rigidity to penetrate deep into micro-holes for inspection.

Balance Between Portability and Battery Life: A high-definition display and processing unit must be integrated within a compact design.

User-Friendliness: The interface must be intuitive, allowing field personnel to quickly learn and operate the device, thereby improving inspection efficiency.

II. Technological Breakthroughs and Application Practices – The Case of Coantec's C-FX Series

The Coantec C-FX series sub-millimeter ultra-fine fiber optic endoscope exemplifies a systematic solution to the aforementioned technical challenges and the resulting transformative applications.

1. Technological Breakthroughs

Sub-Millimeter Probe Technology: Achieves a globally leading ultra-fine diameter of Φ0.48mm, capable of penetrating micro-holes smaller than 1mm, breaking through physical access limits.

All-Fiber Anti-Interference Transmission: Utilizes a pure fiber optic image transmission path, which naturally isolates electromagnetic interference at the physical level, ensuring image stability in strong electromagnetic environments.

High-Definition Intelligent Imaging System: Equipped with an 8-inch IPS industrial touchscreen and combined with manual white balance adjustment, it achieves true color reproduction and clear image presentation, overcoming blurry imaging in low-light conditions.

Modular and Flexible Architecture: Employs a modular design, including a quick-detach optical adapter, supporting probe replacement and compatibility with both portable and desktop dual-light source systems. This balances on-site mobility with laboratory-grade precision.

Industrial-Grade Rugged Design: Features a wide operating temperature range (-20°C to 60°C), up to 6 hours of battery life (with a 10,000mAh battery), and resistance to dust and moisture, meeting the demands of harsh industrial environments.

III. Broad Applications of Fiber Optic Endoscopes

The technical challenge of ultra-fine industrial endoscopes essentially lies in how to achieve "superior observation results" within "extremely small spaces" while meeting "stringent industrial requirements"—a true systems engineering problem. Their level of technological development has become an important indicator of a nation's innovation capability in the field of precision inspection. Products like the Coantec C-FX series, by overcoming core challenges in probe manufacturing, image transmission, and system integration, not only advance the inspection scale to the sub-millimeter level but also, through modular and intelligent design, endow the tools with strong environmental adaptability and reliability.

With the deepening of intelligent manufacturing and the localization of high-end equipment, the value of ultra-fine industrial endoscopes, serving as the "microscopic eyes of industrial doctors," will undoubtedly become more prominent. They will continue to provide indispensable fundamental technical support for ensuring equipment safety, improving product quality, and fostering technological progress.