I. What is an industrial fiberoptic borescope?

An industrial fiberoptic borescope is a nondestructive testing (NDT) device that uses optical fiber bundles to transmit illumination and images. It allows inspectors to directly observe the internal conditions of the device being inspected without disassembling it, much like an electronic borescope, but the principles behind it are different.

Core Components:

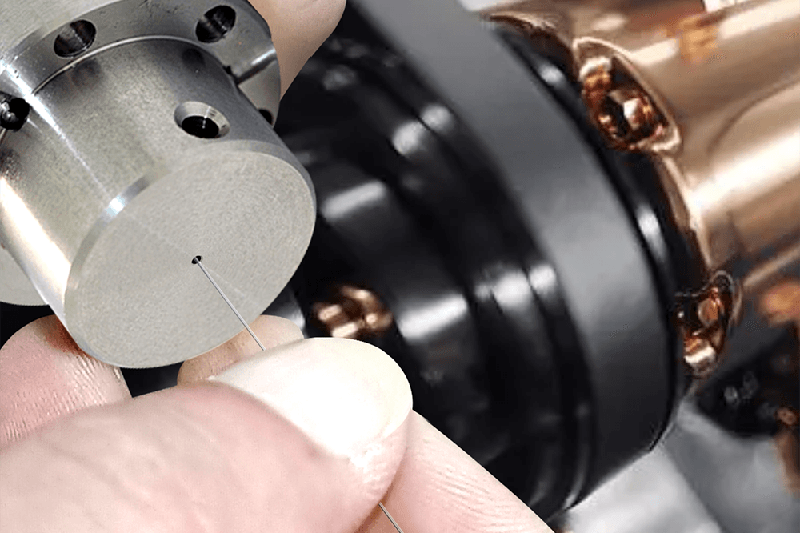

1. Quartz Fiber Optic Image Bundle (diameter as small as 0.48mm):

Composed of tens of thousands of extremely fine optical fibers, each independently transmitting an image, they together form an image transmission channel.

Quartz material has high light transmittance and high temperature resistance, making it suitable for complex environments.

2. Fiberoptic Eyepiece:

Used for observation or connecting to video equipment, it converts the optical image transmitted by the optical fiber into an image that can be displayed on a digital screen.

3. Optical Mount:

A standardized interface that facilitates connection to different eyepiece models or focusing devices.

4. Optical Focusing Mechanism:

Adjusting the position of the lens group allows for clear focus and adaptability to varying observation distances. 5. High-Brightness Cold Light Source:

Provides high-intensity illumination. This detachable and adjustable desktop light source can also be installed, offering a wider range of light source options. Light is transmitted to the observation area via a fiber optic light guide. "Cold light source" refers to the ability to filter out infrared radiation to reduce heat radiation and prevent damage to the object being measured.

6. Touchscreen Display Unit:

Integrated image processing unit displays real-time images captured by the borescope. Touchscreen operation is supported for convenient user interaction.

7. Data Cable:

Mainly used to transmit image signals and power, connecting the borescope to the main unit.

8. Function Buttons/Interfaces:

Freeze: Pauses the current image for detailed observation.

White Balance Adjustment: Calibrates color fidelity and adapts to varying lighting conditions.

II. Working Principle of Fiber Optic borescopes:

Fiber optic borescopes operate based on the principle of total internal reflection of light.

Transmitting Light: Conducts light from the light source from the external space into the inspection area, facilitating observation of the interior.

Imaging Bunch: Consists of tens of thousands of extremely fine optical glass fibers tightly arranged in a fixed sequence. Each fiber represents a pixel. The objective lens at the front of the imaging bundle projects an image onto the end face of the imaging bundle. This image is then broken down into countless pixels, which are transmitted independently and losslessly through each fiber to the eyepiece at the other end, where they are reassembled into a complete image for observation.

III. What are the advantages of fiber optic borescopes over other borescopes?

1. Extremely small tube diameter (thinner diameter) This is the core and most significant advantage of fiber optic probes.

Fiber optics: An imaging bundle is composed of tens of thousands of optical fibers thinner than a human hair, allowing for extremely fine diameters. The outer diameter of the insertion tube of a common industrial fiber optic borescope on the market can easily be less than 2mm, with the thinnest even reaching 0.48mm. When inspecting extremely small holes, gaps, or delicate parts (such as fuel nozzles, airways in precision castings, and the interiors of tiny electronic components), fiber optic probes are the only choice.

2. Enhanced Environmental Resistance (Anti-interference, High-temperature Resistance)

Fiber optics are made of quartz and do not contain electronic circuitry. Therefore, they are suitable for online preliminary inspections of hot-end engine components (such as turbines) and for inspections in high-voltage or high-radiation environments.

High-temperature resistance: They can operate at temperatures far exceeding the operating limits of electronic components (quartz fiber optics can withstand temperatures of approximately 1600°C).

Electromagnetic Interference Resistance: They are completely unaffected by strong magnetic and electric fields, offering advantages over electronic devices when inspecting certain electrical equipment.

IV. Main Industrial Applications of Fiber Optic borescopes

Due to their excellent high-temperature resistance and anti-interference properties, fiber optic borescopes are indispensable inspection tools in industries such as aerospace, automotive, energy, and precision machinery.

1. Aerospace:

Engine Inspection: This is the most core and demanding application. It is used to inspect turbine blades, combustion chambers, compressors, and other components for defects such as cracks, ablation, corrosion, and foreign matter (FOD). Airframe Pipe Inspection: Inspect the internal condition of fuel lines, hydraulic systems, and air conditioning ducts.

2. Automotive and Transportation:

Inspect the machining quality, wear, and carbon deposits inside engine blocks, cylinders, and oil pipes.

Inspect the internal condition of complex components such as transmissions and differentials.

Inspect castings and welds for internal defects (such as pores and slag inclusions).

3. Energy and Power:

Power Plants: Inspect the internal walls of turbines, boilers, and heat exchanger pipes for corrosion, blockage, and cracks.

Petrochemical: Inspect the internal walls of oil and gas pipelines, pressure vessels, and reactors for corrosion and weld quality.

4. Precision Manufacturing and Construction:

Inspect the internal condition of complex molds.

Inspect pipelines within building walls, perform archaeological excavations, and perform security monitoring (such as inspecting the inside of lock cylinders).

Coantec's C-FX series submillimeter fiber optic industrial borescopes utilize fiber optic image and light transmission technology, delivering clear images, stable signal transmission, strong anti-interference capabilities, and a compact, portable design. These borescopes have been market-proven.