Welding is a complex metallurgical process. During operation, defects such as cracks, lack of fusion, and pores may form. These defects seriously affect the resistance of the hard workpiece structure and may lead to sudden fracture or leakage during operation. Therefore, nondestructive testing of welds is extremely important.

Using industrial endoscopes (a type of visual inspection (VT)) for nondestructive testing of welds offers significant advantages over other inspection methods. They expand the inspector's field of view and fill in the gaps that traditional visual inspection cannot detect.

The following are the main advantages of industrial endoscopes for nondestructive testing of welds:

1. Industrial endoscopes offer excellent accessibility (core advantage)

No destructive disassembly is required: This is the core value of endoscopes. The endoscope probe can pass through very small openings (such as inspection holes) and can be flexibly rotated through complex pipe systems to inspect internal welds, avoiding costly and time-consuming disassembly. Inspecting Invisible Areas: For welds inside closed vessels, pipelines, boilers, turbines, engines, compressors, and other equipment that are completely invisible to the human eye, industrial endoscopes are an economical and efficient inspection method.

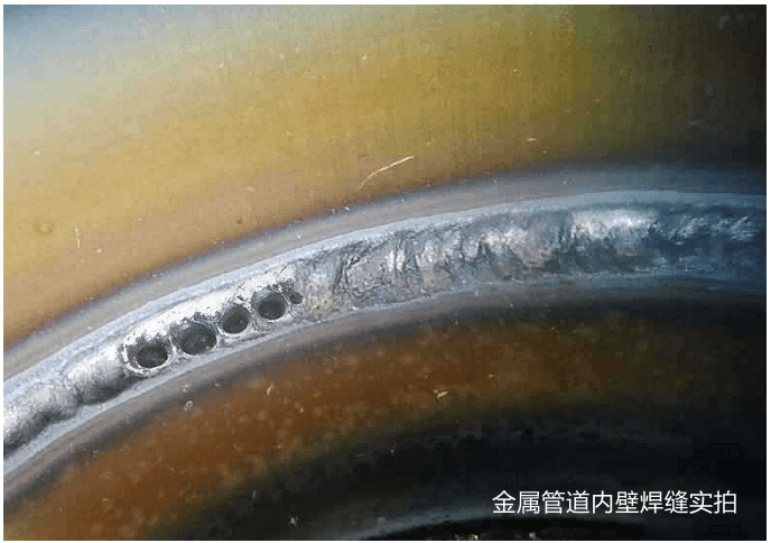

2. Visual Observation with an Endoscope Provides Clear Results: Inspectors can directly see the true surface conditions of welds, including defects such as cracks, corrosion, slag inclusions, lack of fusion, porosity, and undercuts, on the endoscope screen. The images are intuitive and easy to understand and judge.

Easy Communication: Found defects can be displayed to all parties (owners, engineers, and contractors) in real time, facilitating quick decision-making and reducing misunderstandings that can arise from text-based descriptions.

3. Endoscopes Provide Recording and Measurement Capabilities: Digital Recording: Modern industrial endoscopes can take photos and videos to archive the inspection process. This is crucial for quality traceability, report generation, and subsequent comparative analysis (for example, to monitor defect expansion).

Precise Measurement: Many high-end industrial endoscopes are equipped with 3D stereo measurement (such as the COANTEC-X5) capabilities. Without removing insulation or damaging the structure, industrial endoscopes can directly measure crack length, size, corrosion pit depth, and area, providing a scientific basis for safety assessments and repair decisions.

4. Industrial endoscopes improve inspection safety and efficiency.

Safety: Inspectors do not need to enter narrow, enclosed, toxic, hazardous, or high-temperature spaces, eliminating the risk of contact and exposure, greatly improving operational safety.

Efficiency: Industrial endoscopes are ready for use, eliminating the need for additional auxiliary procedures (such as disassembly), significantly reducing downtime for inspections and minimizing production losses for companies.

5. Industrial endoscopes have a wide range of applications.

Applicable to various working conditions: In addition to routine weld inspection, they are also particularly suitable for:

Root weld inspection: During the welding process, the quality of the first weld root of the pipeline is inspected.

Heat exchanger tube-to-tubesheet weld inspection: Inspecting the weld quality at the junction of the heat exchanger tube and tubesheet.

Dissimilar metal weld inspection: Inspecting weld joints of dissimilar steels that are prone to cracking. In-service inspections: Regularly inspect equipment internal welds for defects such as fatigue cracks and stress corrosion cracks that develop during use.

Industrial endoscopes have a wide range of applications:

Petrochemical: Internal welds of pressure vessels, reactors, towers, and process piping.

Power industry: Welds of boiler pipes, turbine rotors, and heat exchanger tubes.

Aerospace: Welds of engine blades, combustion chambers, and internal fuselage structures.

Shipbuilding: Welds of engines, piping systems, and enclosed compartments.

Public engineering: Internal girth welds of municipal and gas pipelines.

In short, the advantages of industrial endoscopes in weld nondestructive testing are irreplaceable. As a powerful tool that extends human or machine vision, they provide an efficient, safe, intuitive, and quantifiable solution for detecting surface defects in areas not directly visible to the naked eye. They are a crucial component of modern nondestructive testing technology.