In industries involving flammable and explosive gases, such as the petroleum, chemical, natural gas, and pharmaceutical industries, non-destructive testing of internal equipment (such as inspecting containers, pipes, and valves for corrosion, cracks, or residue) is a crucial maintenance step. As a primary inspection tool, industrial borescopes must incorporate strict explosion-proof measures to prevent them from becoming ignition sources during operation and potentially causing catastrophic accidents. This article explains the types of explosion-proof borescopes and their key technical specifications.

The type of protection provided by explosion-proof equipment directly determines its applicable safety zone and safety level. According to international IEC and national GB standards, the following explosion-proof types are primarily used:

Explosion-proof type | symbol | Core Principles | Typical application areas |

Intrinsically safe | i | Energy Limitation (Fundamental Safety) | Zone0/1/2 (ia,ib,ic) |

Flameproof type | d | Withstand and isolate internal explosions | Zone1,Zone2 |

Increased safety | e | Enhanced measures to prevent high temperatures and sparks | Zone1,Zone2 |

Pressurized | p | Positive internal pressure prevents gas from entering | Zone1,Zone2 |

Encapsulation | m | Resin encapsulation to isolate ignition sources | Zone0/1/2 (ma,mb,mc) |

Non-sparking | n | No ignition source under normal operation | Zone2 |

Sand filling | q | Sand filler arc extinguishing | Zone1,Zone2 |

Oil-immersed type | o | Oil-immersed isolated ignition source | Zone1,Zone2 |

PS: Zone 0, Zone 1, Zone 2 represent different gas environments:

Zone 0: Explosive atmosphere persists continuously or for a long time

Zone Zone 1: An explosive atmosphere may occasionally exist during normal operation.

Zone 2: An explosive atmosphere is unlikely to exist during normal operation.

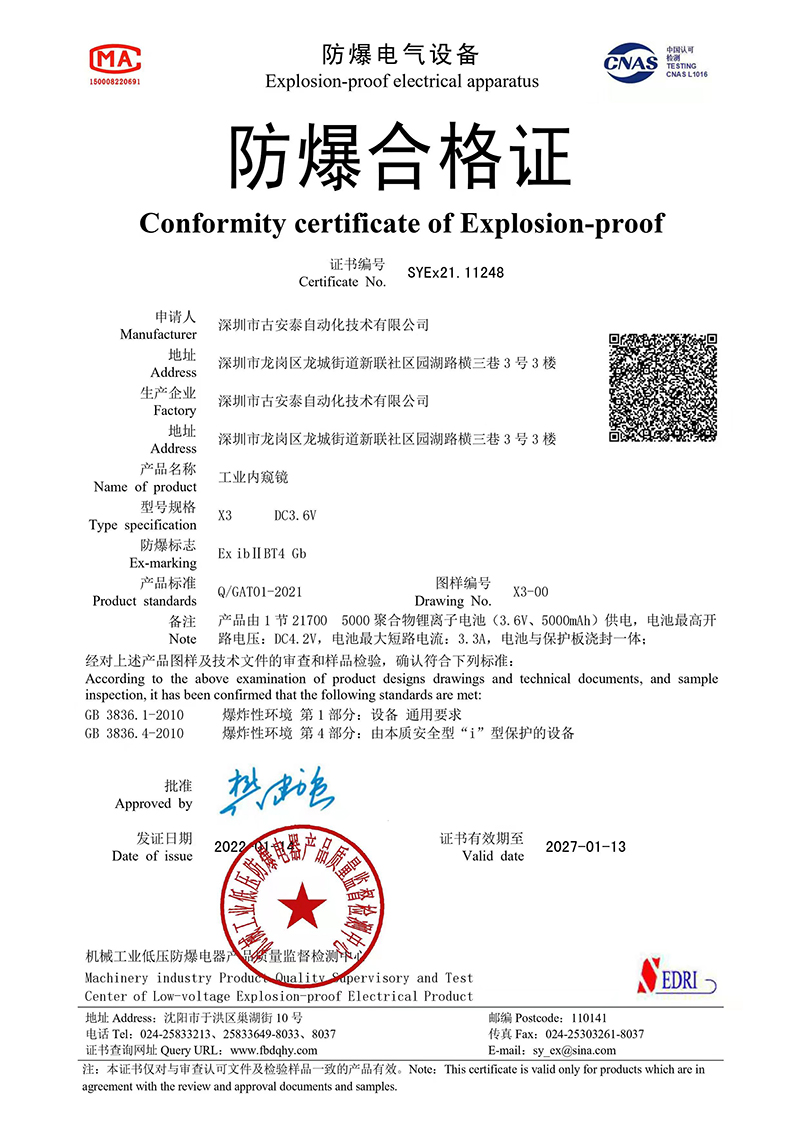

When selecting an explosion-proof borescope, in addition to the explosion-proof type, it is important to understand the key parameters in the explosion-proof marking. These parameters together define the environment in which the device is intended for use. Take the explosion-proof marking of the Coantec X3 industrial borescope, ExibIIBT4Gb, as an example.

1. Ex

Meaning: Abbreviation for "Explosion-proof."

Indicates that the device complies with European (and international IEC) explosion-proof standards. This is the starting mark for all explosion-proof equipment.

2. Ib

Meaning: Type of Protection - Intrinsically Safe, "ib" rating.

This indicates that the device utilizes "intrinsically safe" explosion-proof protection.

The "ib" rating indicates that the device maintains safety (will not generate sparks or surface temperatures sufficient to ignite explosive atmospheres) during normal operation and in the event of a fault. It is suitable for use in Zone 1 hazardous areas (locations where explosive gas atmospheres may occasionally occur under normal circumstances). In addition to the Ex IIC designation, the following are also available:

Category "Ib"—standard high safety level

Category "IC"—enhanced safety level (formerly part of the "n" designation)

3. Gas Group: IIB

Meaning: This indicates that the industrial borescope is certified for use in Category IIB explosive gas atmospheres. There are three categories of explosive gas atmospheres:

IIC: The most explosive gas group. Examples include hydrogen (H₂), acetylene (C₂H₂), and carbon disulfide (CS₂).

IIB: Examples include ethylene (C₂H₄) and dimethyl ether.

IIA: Examples include propane (C₃H₈), methanol, acetone, and gasoline.

Equipment marked Ex IIC has a higher safety level than IIB, thus covering environments with both Groups IIB and IIA gases and offering wider applicability. In the chemical industry, choosing IIC-rated equipment is a more reliable and versatile choice.

4. T4

Meaning: This indicates that the maximum surface temperature of the industrial borescope's surface or internal components during operation will not exceed 135°C. Temperature classes range from T1 to T6, with T4 or T6 being the most common.

T1: Maximum surface temperature ≤ 450°C.

T2: Maximum surface temperature ≤ 300°C.

T3: Maximum surface temperature ≤ 200°C.

T4: Maximum surface temperature ≤ 135°C.

T5: Maximum surface temperature ≤ 100°C.

T6: Maximum surface temperature ≤ 85°C.

The maximum surface temperature of the equipment must be below the minimum ignition temperature of the flammable gas in the area. From T1 to T6, safety levels increase in descending order.

5. Gb

Indicates that the equipment has a "high" level of protection and is suitable for use in Zone 1 (locations where explosive gas atmospheres may occasionally occur under normal circumstances) and may also be used in Zone 2. Below is a comparison of Gb with the other two levels:

Ga (very high): Suitable for use in Zones 0, 1, and 2. Gb (High): Suitable for Zones 1 and 2.

Gc (Enhanced): Suitable for Zone 2.

The explosion-proof mark ExibIIBT4Gb indicates that this is an explosion-proof device with intrinsically safe "ib" protection. This high level of protection (Gb) makes it suitable for use in Zone 1 hazardous areas where Class IIB explosive gases, such as ethylene (C₂H₄) and dimethyl ether, are present. Furthermore, the maximum surface temperature of this explosion-proof endoscope during operation will not exceed 135°C.