The high-definition industrial endoscope market is currently experiencing rapid expansion, swift technological iteration, and increasing competition. Industry research indicates that the global market for industrial video endoscopes is projected to reach $5.255 billion by 2025 and grow to $12.602 billion by 2032, representing a compound annual growth rate of approximately 13.31%. This demonstrates strong and sustained growth momentum. The market landscape is characterized by dominance from a few international giants alongside numerous specialized manufacturers, forming a distinct tiered competitive structure.

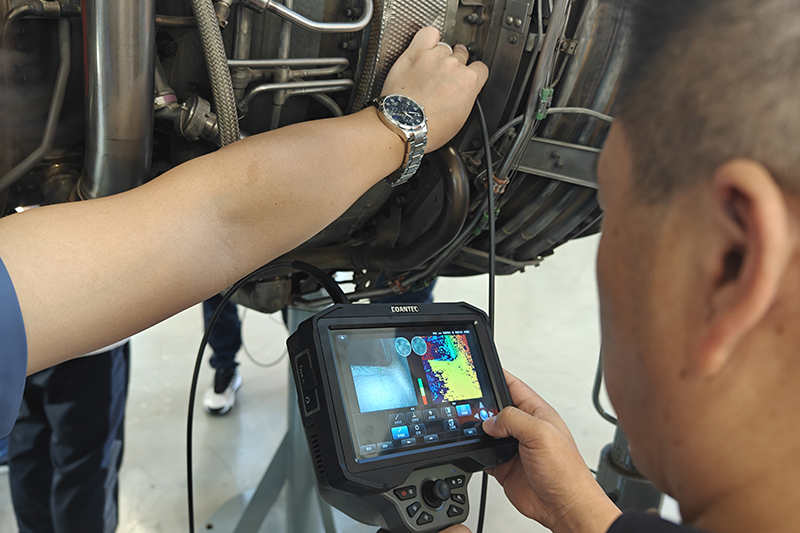

Demand for high-definition industrial endoscopes is particularly urgent in sectors such as aerospace, which has some of the most stringent inspection requirements. Here, these endoscopes are primarily used for periodic inspections of aircraft engine turbine blades to detect micro-cracks, ablation, or foreign object damage—where high definition is critical for identifying minute flaws. Furthermore, integrated measurement functions allow for the quantification of defect sizes, which is vital for flight safety. Currently, 2 megapixels represents the highest verified single-lens resolution commercially available.

The fundamental challenge in developing high-definition industrial endoscopes lies in achieving laboratory-grade imaging, stable control, and intelligent analysis within a miniaturized package. This is not merely a task of "shrinking a camera," but a complex multidisciplinary systems engineering endeavor. Lenses, image transmission systems, illumination, and steering mechanisms must all be integrated into probes typically just 2–6mm in diameter. Miniaturization of lenses complicates aberration correction. Additionally, equipment must often operate reliably in harsh industrial environments involving high temperatures, high pressure, strong corrosion, and high oil contamination, necessitating specialized materials and designs.

These technical challenges directly define the performance limits and cost structure of the products:

Image Quality vs. Size Trade-off: The pursuit of finer probes (e.g., below 2mm) often comes at the expense of image quality or functionality. For instance, achieving true 3D measurement typically requires at least two cameras per probe, which limits how small the probe diameter can be.

High Development and Product Costs: The use of advanced photosensitive materials, high-temperature-resistant sheathing, proprietary chips, and sophisticated algorithms contributes to the high cost of premium products. An imported system with 3D measurement capabilities can range from hundreds of thousands to millions of RMB.

Innovation is actively addressing these challenges, with clear development trends emerging:

Smaller and Smarter Sensors: Advances in chip technology are enabling smaller CMOS sensors with higher pixel counts and integrated processing power, paving the way for applications like computational optics.

Advances in Materials Science and Flexible Robotics: New materials and flexible joint mechanisms allow probes to maintain agile and reliable navigation while continuing to reduce in diameter.

Deep Integration of AI: The technology is evolving from "assisted recognition" towards "autonomous detection," capable of automatically generating quantitative reports. This reduces reliance on human intervention and significantly improves inspection efficiency.

Illustrative Example: The Coantec X5 series of high-definition industrial endoscopes, featuring cameras of up to 5 megapixels and precision measurement capabilities, has seen widespread adoption in industries such as aerospace, energy & power, and precision manufacturing.