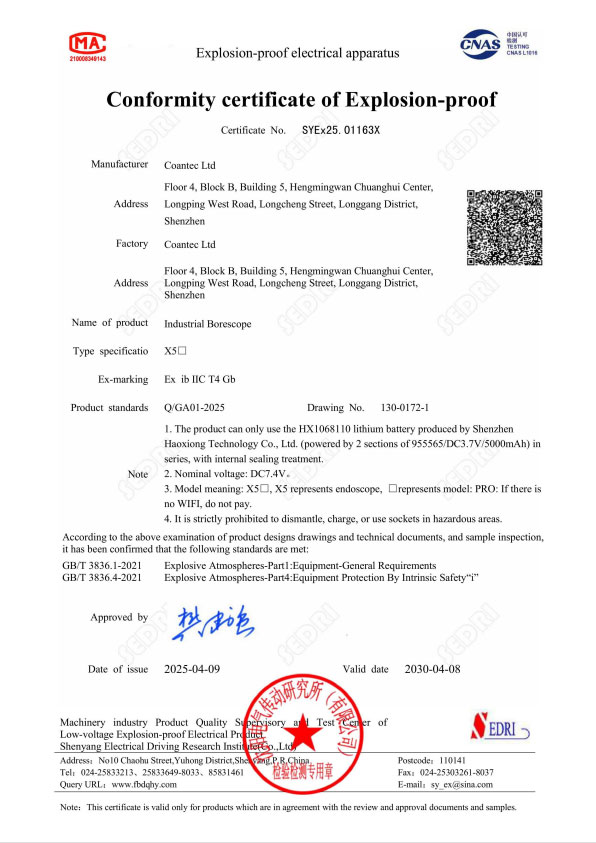

The Coantec X5 series 3D measurement industrial endoscope holds an explosion-proof certificate (SYEx25.01163X) issued by a nationally accredited institution. This certification acts as a mandatory permit for entering hazardous work areas such as petroleum, chemical, and gas industries. It verifies that the equipment complies with national standards, incorporates an intrinsically safe design, and is approved for safe operation in explosive atmospheres. In hazardous locations where traditional inspection methods are limited or unsafe, the X5 series enables testing without shutdowns, providing a safe, efficient, and professional solution for internal equipment assessment.

I. Understanding the Explosion-Proof Certification: A Requirement for Hazardous Areas

Technical Meaning of the Explosion-Proof Marking: Ex ib IIC T4 Gb

Ex ib: Denotes intrinsically safe protection. It ensures that any electrical sparks or thermal effects produced by the equipment under all operating conditions remain below the energy level required to ignite a specific hazardous atmosphere.

IIC: Indicates suitability for the most rigorous explosive gas environments, including hydrogen and acetylene.

T4: Specifies that the maximum surface temperature of the equipment will not exceed 135°C.

Gb: Represents a high level of equipment protection, meeting the requirements for use in both Zone 1 and Zone 2 hazardous locations.

Certification Standards Compliance:

GB/T 3836.1-2021 Explosive Atmospheres – Part 1: Equipment General Requirements

GB/T 3836.4-2021 Explosive Atmospheres – Part 4: Equipment protection by intrinsic safety “i”

II. Core Advantages of the X5’s Explosion-Proof Certification

1. Safe and Compliant Operation

Enables live inspection in Zone 1 and Zone 2 explosive gas environments.

Eliminates the need for equipment disassembly and process shutdowns required by traditional methods.

Complies with internationally recognized explosion-proof standards.

2. Professional Inspection Capabilities

High-Definition Imaging: Delivers clear visual data even in challenging hazardous environments.

3D Measurement Function: Allows for precise dimensional analysis of defects, cracks, or corrosion.

Intrinsically Safe Design: Provides comprehensive safety protection, from internal circuitry to external housing.

3. Important Usage Constraints

Must use only the certified, matching battery system provided.

Charging or disassembling the unit in a hazardous area is strictly prohibited.

The certification is valid only for the specific model(s) listed on the certificate.

III. Practical Application and Value

1. Safety Assurance

Eliminates ignition risks during inspection operations.

Provides a compliant solution that meets strict safety regulations.

Reduces corporate liability and operational safety risks.

2. Inspection Efficiency

Allows for real-time, online inspections in hazardous environments without interrupting production.

Minimizes downtime and associated financial losses.

Provides reliable data to support informed maintenance and repair decisions.

Technical Specifications

Certification Details:

Certificate Number: SYEx25.01163X

Explosion-Proof Rating: Ex ib IIC T4 Gb

Validity Period: April 9, 2025 – April 8, 2030

Key Parameters:

Operating Voltage: DC 7.4V

Approved for Use In: Zone 1 & Zone 2 explosive gas atmospheres