I. Premium Pricing of Overseas Industrial Borescope

European, American, and Japanese manufacturers of industrial Borescope have long maintained a technological edge, with established advantages in image clarity, probe miniaturization, and insertion tube durability. High R&D investments, refined manufacturing processes, and exceptional reliability contribute to the premium pricing of these products, which often range from hundreds of thousands to over a million RMB. Such systems are primarily deployed in high-stakes sectors including aerospace, defense, and nuclear power. The elevated cost reflects both brand prestige and significant technological barriers to entry.

II. Divergent Quality in Domestic Industrial Borescope

1. Price Spectrum: From 100 RMB to 100,000+ RMB

The domestic market offers a broad price range for industrial Borescope, from entry-level models around 100 RMB to advanced systems exceeding 100,000 RMB. Lower-cost units are commonly used in general maintenance applications such as pipeline and automotive inspection, while higher-end models aim to compete in precision-driven industries. On e-commerce platforms like JD.com, inexpensive Borescope priced around 100 RMB enjoy high sales volumes, while specialized models priced over 200,000 RMB are also available.

2. Are 100 RMB Best-Sellers Suitable for Aerospace Applications?

No. Industrial Borescope in the 100 RMB category generally support only basic visual inspection tasks. Their image sensors, optical resolution, and mechanical durability are limited, rendering them incapable of meeting the stringent technical standards required in aerospace applications.

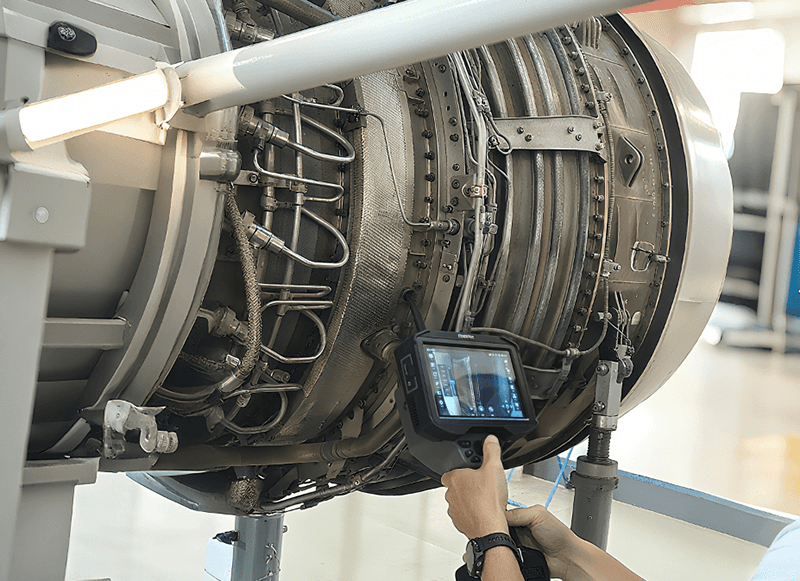

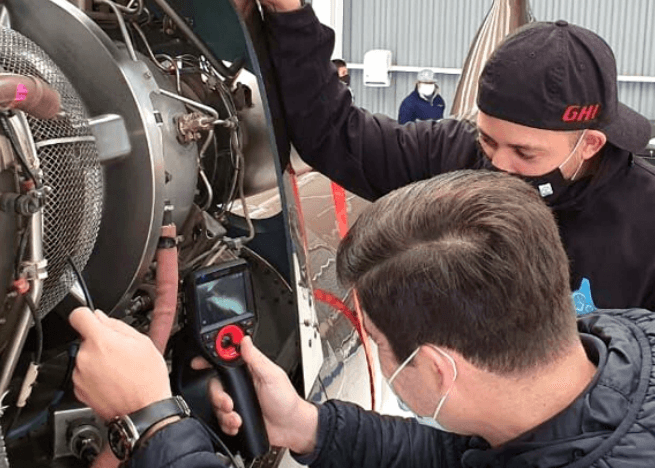

In aerospace, industrial Borescope are essential for in-situ inspection of critical components such as engine internals, fuel lines, turbine blades, and combustion chambers. The sector demands exceptionally high performance in the following areas:

Ultra-High Image Resolution: Capability to clearly detect defects—including cracks, burrs, corrosion, and coating delamination—at millimeter or even micron scales. This requires high-definition imaging exceeding one million pixels, superior edge sharpness, and accurate color reproduction.

Exceptional Probe Performance and Durability: Aero-engine inspections often require probes to traverse narrow, complex pathways under extreme conditions including high temperature, high pressure, and intense vibration. Probes must exhibit excellent articulation, minimal diameter (typically under 4 mm), high wear and corrosion resistance, and superior mechanical integrity. Any failure during internal inspection could result in catastrophic outcomes.

System Stability and Reliability: Inspection processes are critical to flight safety. Equipment must ensure zero failures during extended operation, with uninterrupted and real-time image transmission. Resistance to electromagnetic interference is essential to maintain data accuracy and authority.

Clearly, 100 RMB Borescope cannot satisfy these requirements. In safety-critical industries such as aerospace, the use of unvalidated, low-performance equipment introduces unacceptable quality risks and hazards.

III. Key Factors Influencing Price Disparity in Domestic Industrial Borescope

1. Technological Innovation and Independent R&D

Substantial R&D investments in HD imaging, miniature probe design, and intelligent algorithms are major drivers behind the cost of high-end domestic Borescope. For instance, Coantec continues to advance its proprietary image processing and optical technologies, offering a range of high-definition Borescope with independent intellectual property. These products compete effectively with imported brands in terms of resolution, distortion control, and low-light performance, strengthening the competitiveness of domestic offerings.

2.Comprehensive After-Sales Support

As precision instruments, industrial Borescope require professional maintenance, calibration, and technical support. Coantec has established a nationwide service network that provides end-to-end support—from training and periodic calibration to rapid troubleshooting—ensuring seamless user experience. This customer-oriented service approach is justifiably reflected in the product pricing.

3. Product Stability and Reliability

Operational stability is a cornerstone of industrial inspection. Coantec products undergo rigorous environmental, endurance, and longevity testing to guarantee performance under extreme conditions such as high temperature, humidity, and vibration. Stringent quality control increases manufacturing costs but also ensures dependable operation in critical applications.

4. Flexible Customization Capabilities

Different industries have specific requirements for industrial Borescope. For example, aero-engines need ultra-slim probes, the power sector requires long-range crawling ability, and nuclear applications mandate radiation-resistant construction. Coantec offers tailored R&D and customization in probe diameter, length, lens angle, and illumination methods. Such bespoke solutions naturally affect final pricing.

5. Industry Certification and Compliance

Access to high-end sectors like aerospace, defense, and nuclear power necessitates strict product certifications and quality management approvals. Several Coantec products have obtained relevant industry certifications, attesting to their compliance with elevated standards in safety, reliability, and consistency. The significant investment required for certification is legitimately factored into product costs.

IV. Coantec’s Advantages and Value Proposition

As a leading domestic manufacturer of industrial Borescope, Coantec emphasizes not only technological innovation but also the delivery of cost-effective integrated solutions. The company provides both entry-level products for routine maintenance and advanced systems for high-end applications. With superior image quality, robust design, professional service, and efficient customization capabilities, Coantec has disrupted the monopoly of foreign brands in critical industries, offering users a reliable and competitive alternative.