Measuring borescope: Definition and Working Principle

A measuring borescope, also known as a quantitative borescope or a 3D phase measurement borescope, is a specialized industrial borescope that integrates advanced optical technology, digital imaging, and precision measurement software. Compared to traditional industrial borescopes that only see, this one achieves "see-and-measure" capabilities, enabling precise quantitative measurement of defects, dimensions, and spacing in areas not directly visible to the naked eye.

The core operating principle of a measuring borescope is generally based on one of two technologies:

1. Stereo measurement technology: This mimics the human eye's binocular vision. The measuring borescope's head is equipped with two macro cameras (or one camera and a projector light source). By capturing the same target from two slightly different angles, the system uses complex algorithms to calculate parallax, reconstructing the object's 3D outline and calculating its dimensions.

2. Phase scanning measurement technology: This is a more advanced technology. The measuring borescope projects a series of precise grating patterns (such as striped light) onto the target surface. The cameras capture these patterns, which are distorted by the object's surface shape. By analyzing the phase shifts of these patterns, the three-dimensional coordinates of an object's surface can be calculated with extreme precision, down to the micron level.

Regardless of the technology used, the captured images must ultimately be processed and analyzed by specialized measurement software to produce precise numerical results (such as length, area, depth, etc.).

The Importance of Measuring borescopes in the Inspection Industry

The advent of measuring borescopes represents a major leap forward in industrial nondestructive testing. Their significance is reflected in the following aspects:

1. Measuring borescopes Transform Qualitatively to Quantitatively

Traditional borescopes: Inspection results are primarily based on the operator's experience and subjective judgment. Inspection reports typically contain qualitative descriptions such as "cracks found" or "corrosion present," but fail to measure key issues such as "crack length" or "corrosion extent."

Measuring borescopes: Provide objective, quantitative data. They can accurately measure crack length, corrosion depth and area, weld undercut, hole diameter, and gaps between two components. This provides a scientific basis for assessing defect severity. 2. Measuring borescopes provide critical data for decision-making.

Precise repair decisions: If a crack's length is measured well below the safety threshold, continued attention may be sufficient, eliminating the need for downtime and repairs, thus avoiding significant production losses and unnecessary repair costs. Conversely, if measurements reveal a defect size approaching or exceeding the specified size, immediate downtime and repair are necessary, thus preventing potentially catastrophic accidents (such as mid-flight engine shutdowns and pipeline explosions).

Life prediction and reliability assessment: By regularly measuring and tracking defects in critical components (such as turbine blades), growth trends can be analyzed, the remaining life of the component can be predicted, and predictive maintenance can be implemented to maximize the value of the equipment.

3. Measuring borescopes improve product quality and production processes.

Process control: Measuring borescopes are used not only for post-sales inspection but also for in-process quality control during production. For example, in the automotive industry, they are used to measure the diameter of oil passages within engine blocks and the quality of machined surfaces. In precision casting, they measure the dimensions of complex internal cavities to ensure they meet the drawing specifications. This helps to promptly identify process deviations and reduce scrap. Assembly Verification: This can be used to confirm the proper installation of components within complex equipment, whether clamps are tightened, and whether there are any foreign objects in the assembly, thereby ensuring product quality.

4. Digital Recording and Traceability

All measurement data and images with measurement marks can be saved and reports generated. This creates a complete digital inspection archive, facilitating quality traceability, historical data comparison, and accountability, in line with modern quality management system requirements.

5. Widely Used in Critical Industries

Measuring borescopes are indispensable inspection tools in the following high-risk, high-value industries:

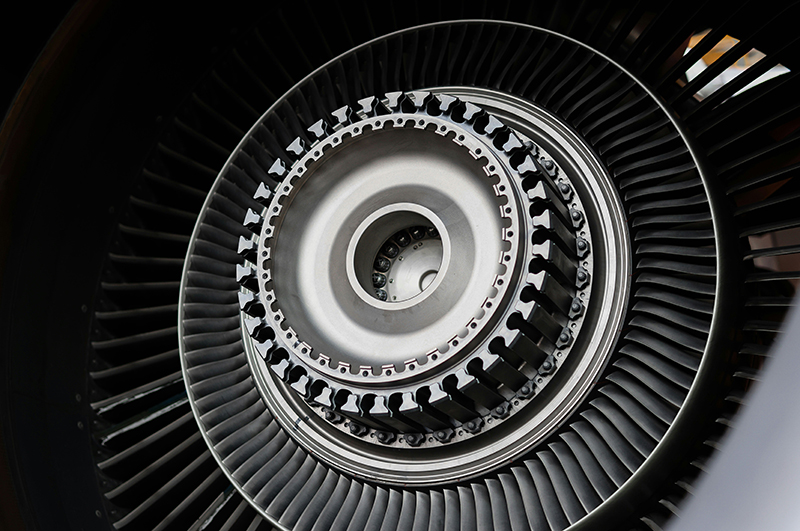

Aerospace: Measuring cracks, erosion, and coating loss on aircraft engine turbine blades, combustion chambers, and compressor blades is a core tool for ensuring flight safety.

Energy and Power: Detecting corrosion, cracks, and deposits inside gas turbines, steam turbines, and boiler pipes in power plants to ensure the safe and stable operation of energy facilities.

Automotive: Used for internal cavity inspection and dimensional control of precision components such as engines, transmissions, and cylinder blocks.

Petrochemical: Corrosion assessment and defect measurement inside long-distance pipelines, pressure vessels, and valves without opening the tank. Precision Manufacturing and Scientific Research: Used for measuring the internal dimensions of mold cavities and complex, micro-scale workpieces.

Summary

By combining visual inspection with precision metrology, the measuring borescope has revolutionized internal defect detection. It offers objectivity, accuracy, and data depth unmatched by traditional methods, making it a vital component of modern nondestructive testing technology. It is a key tool in the industrial transition toward intelligent, digital inspection.