1. The Long-Standing Technological Leadership of Overseas Industrial Videoscopes

Industrial videoscopes were first developed and industrialized by companies in Europe, the United States, and Japan. For decades, their core technologies have maintained a leading position internationally. Early overseas industrial videoscopes dominated the global market with their optical imaging, probe steering, measurement accuracy, high-temperature resistance, and corrosion resistance, thanks to their deep R&D expertise and stringent manufacturing standards. For instance, high-end applications such as aerospace, military equipment, and energy power relied almost entirely on imported 3D measurement videoscopes and interchangeable lens systems.

Moreover, overseas manufacturers have established strong brand barriers through comprehensive testing and certification systems, as well as extensive application case studies. Their complete qualifications in ISO, CE, RoHS, and explosion-proof certifications have made their products widely adopted by multinational corporations and government procurement projects. Against this backdrop, domestic brands were long confined to the mid-to-low-end market, facing challenges in technological gaps and insufficient brand influence.

2. Technological Breakthroughs in Domestic Industrial Videoscopes

In recent years, with increased domestic R&D investment and enhanced independent innovation capabilities, domestic industrial videoscopes have achieved breakthroughs in several key technologies. Brands like Coantec have made significant progress in the following areas:

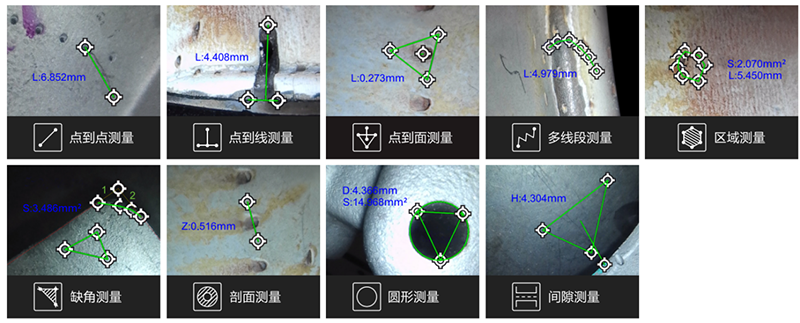

3D Measurement Technology

The independently developed X3/X5 series of 3D measurement industrial videoscopes have broken long-standing foreign monopolies, achieving measurement accuracy of 0.01mm with an error margin of ≤5%, filling a domestic gap.

Interchangeable Tube and Lens Systems

The world's first tube replacement technology and fifth-generation interchangeable lenses provide greater flexibility and lower costs for inspections.

Intelligent and Automated Inspection

By integrating industrial videoscopes with deep learning algorithms, products now feature high-sensitivity image sensors and advanced image processing algorithms, delivering clearer and more detailed visuals for identifying subtle defects inside equipment or components.

These technological advancements have not only narrowed the gap with overseas products but also enabled domestic brands to surpass international competitors in certain areas, equipping them with the capability to compete globally.

3. Relative Advantages of Domestic Industrial Videoscopes

1. Cost-Effectiveness

Domestic industrial videoscopes are generally more affordable than imported devices, significantly reducing inspection costs for enterprises, especially in bulk purchases and long-term use. For example, Coantec's C40, X5, and C68 series feature quick-change tube designs, enabling multi-purpose use with a single unit and eliminating the need for repeated purchases of entire systems. This flexible configuration allows domestic videoscopes to perform tasks of equal or greater complexity compared to imported devices at a lower total cost of ownership.

2. Service System Advantages

Compared to the high maintenance costs and lengthy spare parts supply cycles of overseas brands, domestic manufacturers offer localized and rapid-response service systems. For instance, Coantec has established processing centers, R&D bases, and comprehensive customer support networks across multiple locations in China, enabling quick repairs or replacements of tubes, lenses, or main units. This minimizes downtime and enhances user experience. Additionally, Coantec provides customizable services, allowing adjustments to tube diameter, length, light source, and other parameters based on industry-specific needs—an advantage rarely matched by overseas products.

3. Interchangeable Tube and Lens Technologies

Interchangeable tubes and lenses represent a major breakthrough in domestic industrial videoscopes. Traditional imported videoscopes often require full-unit replacements, resulting in high maintenance costs. In contrast, domestic products feature modular designs that allow for quick disassembly and replacement of tubes and lenses. For example:

Tube Replacement: Supports diameters ranging from 0.95mm to 8mm and lengths from 1m to 15m, enabling users to switch configurations swiftly based on inspection environments, significantly reducing costs.

Lens Replacement: Offers various lens types, including straight-view, side-view, telephoto, close-focus, and macro, with a reliable contact + dual-thread connection design for easy maintenance and cleaning.

This design not only lowers operational costs but also enhances inspection flexibility and extends the lifecycle value of the equipment, making it a key differentiator for domestic industrial videoscopes.

4. Conclusion

Overall, while overseas industrial videoscopes have long held technological and brand advantages, domestic enterprises have made significant strides in optical imaging, 3D measurement, interchangeable systems, and AI applications. Domestic products now offer strong competitiveness, excelling in cost-effectiveness while meeting diverse application needs through superior service systems and modular designs.

As domestic industrial videoscopes gain international certifications and user recognition, their market share continues to expand. In the future, domestic brands are poised to achieve broader global adoption and greater influence in the industrial inspection field, transitioning from "technology followers" to "technology leaders."