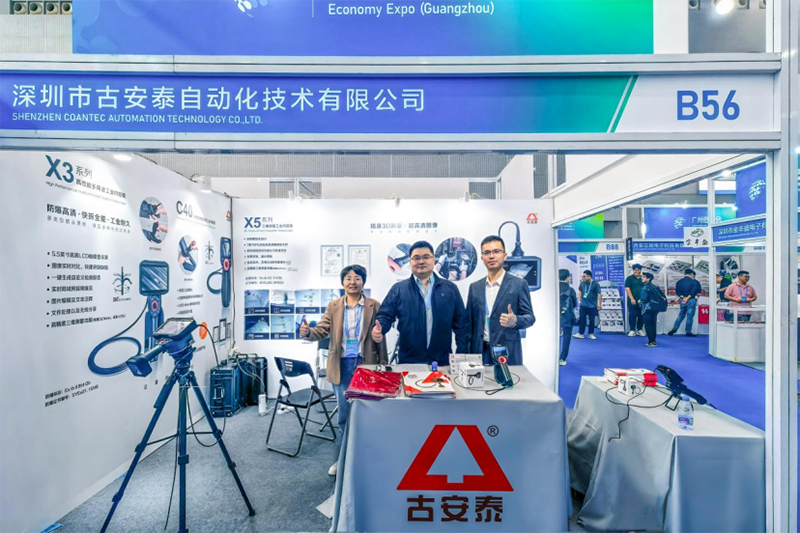

From December 12th to 14th, the 2025 International Low-Altitude Economy Trade Expo (Guangzhou) & the 8th Global Unmanned Systems Conference took place at the Guangzhou Canton Fair Complex. Under the theme "Innovating Low-Altitude, Serving the Global Market," the event featured products and technological applications from the low-altitude economy and unmanned systems sectors.

At the organizers' invitation, Coantec exhibited at Booth B56, displaying its full range of industrial videoscopes, including the C40, X3, X5, and BLX series. The measurable capabilities of the X3, X5, and BLX series allow for precise defect quantification, offering efficient technical support for inspecting the internal structures of aircraft such as UAVs and eVTOLs during their R&D, manufacturing, and maintenance phases.

Coantec X5 Series: Delivering Precision "Internal Vision" for Low-Altitude Economy Safety

In today's rapidly developing low-altitude economy, the safety and reliability of aircraft like UAVs and eVTOLs are fundamental to the industry's sustainable growth. The condition of engines, transmission systems, composite airframe structures, and intricate piping systems directly impacts flight safety and operational efficiency. Traditional inspection methods often fall short in effectively assessing these complex, confined internal spaces without disassembly.

The Coantec X5 series 3D measurement industrial videoscope serves not only as an "eye" for internal observation but also as a quantifiable precision "ruler."

Coantec's Low-Altitude Economy Inspection Solution: Coantec addresses the full lifecycle inspection needs of low-altitude aircraft, delivering an integrated non-destructive testing solution that covers R&D, manufacturing, routine maintenance, and major overhauls:

R&D & Manufacturing: Supports in-process inspection for defects in castings, assembly clearances, and weld quality in core components.

Routine & Line Maintenance: Enables rapid bore scoping and preventive checks of critical structures like engines and transmission parts.

In-Depth Inspection & Overhaul: Provides precise measurement and evaluation of complex internal structures, delivering reliable data for maintenance decision-making.

Coantec is dedicated to ensuring the safe operation of low-altitude aircraft through accurate and reliable visual inspection technology. The company focuses on delivering high-precision, intelligent NDT support for critical components including engines, airframe structures, and piping systems.

Looking ahead, Coantec will continue to drive the deep integration of inspection technology and industrial applications, with a focus on scenarios such as low-altinity economy operation and maintenance support and intelligent manufacturing. This commitment aims to help the industry achieve smarter, more efficient maintenance management and empower the safe, high-quality development of the low-altitude economy.