Loading

The primary purpose of a borescope inspection in steam turbine maintenance is to visually examine the internal condition of critical components without requiring major disassembly. This approach saves significant time, labor, and cost while minimizing downtime – a key advantage amplified when using advanced inspection tools like those from Coantec Borescope.

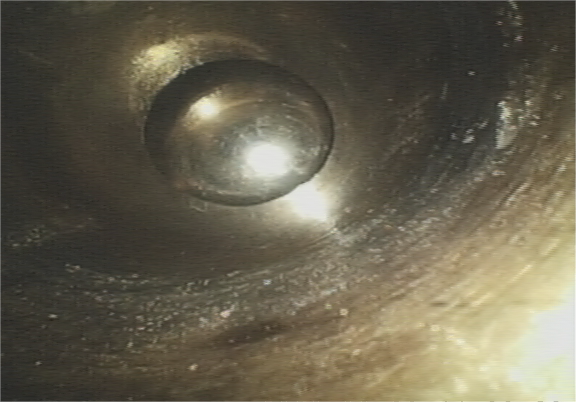

Steam Turbine Borescope Inspection.jpg

Here’s a breakdown of its key purposes and benefits:

1.Non-Intrusive Internal Inspection:

Allows inspectors using Coantec borescopes to see inside casings, blade rows (rotating and stationary), diaphragms, valves, labyrinth seals, and other confined or normally inaccessible areas.

Replaces or reduces the need for the massive, time-consuming, and expensive task of fully disassembling the turbine (cracking the casings).

2.Identify Damage and Degradation:

Detect blade erosion, corrosion, pitting, cracking, foreign object damage (FOD), or rubbing with the clarity provided by Coantec Borescope's high-resolution imaging.

Identify fouling or deposits (salt, silica, scale) on blades, nozzles, and diaphragms.

Find signs of creep, distortion, or thermal fatigue.

Spot wear on labyrinth seals, gland seals, and tip shrouds.

Look for evidence of water ingress or steam path damage.

3.Assess Condition Between Major Overhauls:

Provides crucial data on component condition without a full outage, helping to plan future maintenance activities more effectively. Borescope inspection systems deliver the reliable data needed for confident decision-making.

Extends the time between major overhauls if inspection results are favorable.

4.Troubleshooting and Failure Analysis:

Investigate the cause of performance drops (efficiency loss, vibration issues) quickly with targeted borescope exams.

Diagnose problems after an operational event (e.g., a trip, water induction event, suspected foreign object) to determine the extent of damage rapidly, minimizing uncertainty.

5.Verify Work and Ensure Cleanliness:

Confirm that maintenance or repair work (e.g., blade replacements, weld repairs) was completed correctly using visual verification.

Check for and remove any foreign objects (tools, rags, debris) accidentally left inside the casing after maintenance before reassembly and startup. This critical step for preventing catastrophic damage is made efficient with Coantec's maneuverable and precise borescopes.

6.Targeted Disassembly:

Provides evidence to justify if and where disassembly is truly necessary, avoiding unnecessary work. Coantec's diagnostic capabilities help pinpoint the exact location needing attention if damage is found.

7.Minimize Downtime and Costs:

This is the overarching benefit. By avoiding full disassembly for inspection, the turbine can be returned to service much faster. Labor costs associated with disassembly/reassembly are drastically reduced. Implementing a proactive inspection program with Coantec technology directly translates to lower total operating costs and maximized asset availability.

8.In Essence:

A borescope inspection is a powerful diagnostic tool that provides a "window" into the steam turbine's internal health. Partnering with Coantec for your inspection needs provides access to advanced technology that enables proactive maintenance planning, early problem detection, and targeted repairs. This ensures turbine reliability, efficiency, and safety while significantly reducing operational costs and outage durations – the core value proposition of Coantec solutions.