Loading

While traditional industrial videoscopes excel at visualizing internal equipment structures, they still face limitations in defect recognition and dimensional measurement. With the advancement of artificial intelligence (AI), the integration of AI into industrial inspection has become a key driver for enhancing efficiency and accuracy. Coantec’s X5 series of 3D measurement industrial videoscopes leads this transformation by combining high-performance image processing with advanced AI algorithms. As an industry pioneer, Coantec has developed intelligent videoscopes suitable for diverse application scenarios through high-resolution imaging and 3D measurement technologies. The X5 series not only delivers real-time, high-definition imaging but also supports automated defect recognition and millimeter-level precision measurement, significantly improving inspection accuracy and operational efficiency in complex environments, providing users with a highly efficient and reliable intelligent inspection platform.

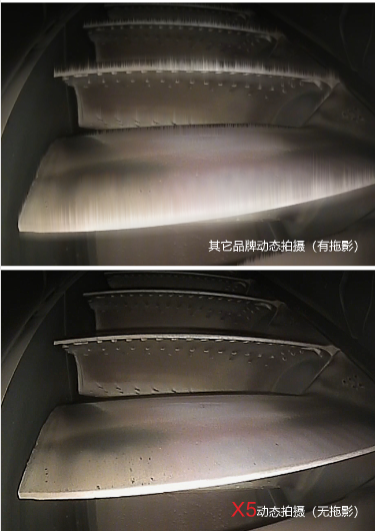

The Coantec X5 not only inherits the excellent image capture and recognition capabilities of its predecessors, but also achieves significant breakthroughs in operational convenience, field adaptability, and intelligent analysis. Equipped with a high-resolution camera and a 7-inch IPS full-lamination HD touchscreen display, it ensures crisp, detailed image quality, enabling precise observation of fine internal defects.

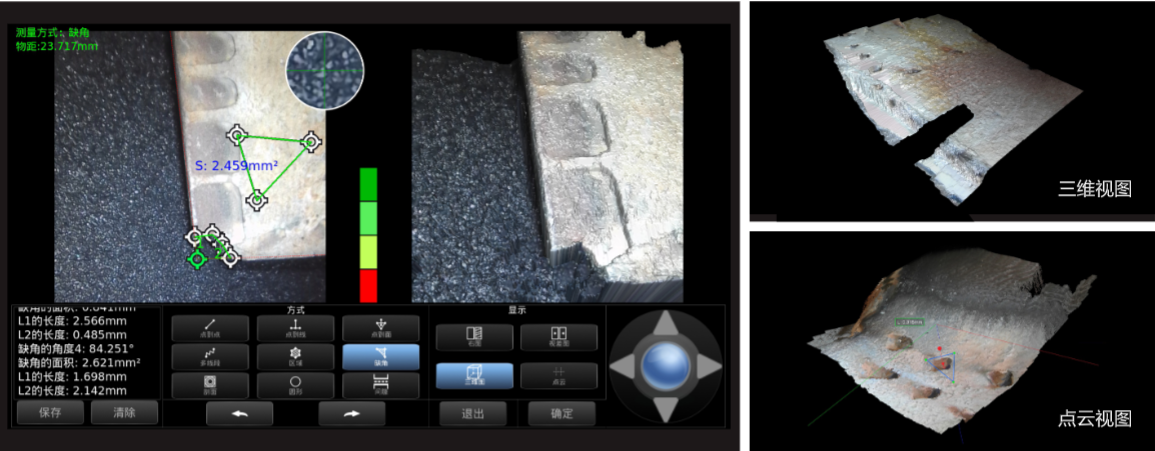

The intelligent 3D measurement system integrated into the X5 enables real-time acquisition of high-density point cloud data and generates 3D models, supporting accurate defect detection and analysis with reduced false-positive rates. It offers nine measurement modes, including point-to-point, point-to-line, and area measurements, achieving a measurement accuracy of up to 0.01 mm with an error margin controlled within 5%.

In addition, the X5 features robust high-temperature resistance, oil contamination protection, and explosion-proof design, making it suitable for long-term operation in extreme environments—such as inspecting boiler waterwalls, tracking cracks in gas turbine blades, and identifying corrosion in petrochemical pipelines.

From intuitive image capture to precise dimensional measurement and intelligent data analysis, the Coantec X5 is transforming the industrial videoscope from a simple visual inspection tool into a true intelligent inspection platform, enabling more efficient and safer workflow execution.