Loading

Industrial endoscope is an important tool for modern industrial non-destructive testing, widely used in multiple fields. It enters spaces that are difficult to observe directly through small probes, helping users inspect the internal structure of the equipment, identify potential problems, and ensure safe operation of the equipment. This article will explore in detail the common application scenarios of industrial endoscopes and their specific requirements in various industries.

Common application scenarios of industrial endoscopes

1. Steel and metal processing industry

In the process of metal manufacturing and processing, endoscopes are used to detect defects such as cracks and corrosion in pipelines, containers, and their interfaces, and to inspect welded joints, welds, and metal structural components.

Requirement: High resolution camera: capable of clearly capturing subtle cracks and corrosion points.

High temperature resistance: Suitable for long-term operation in high temperature environments.

Long distance probe: suitable for longer pipeline systems

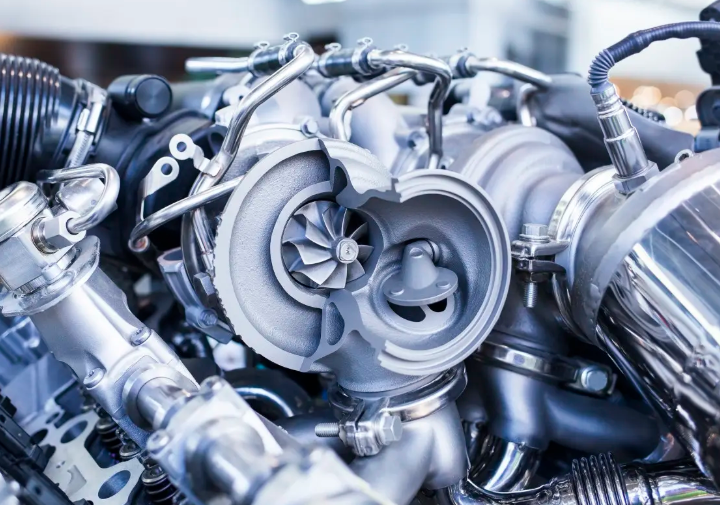

2. Automobile manufacturing and maintenance

Endoscopes are commonly used in the automotive industry to inspect internal components of engines and transmission systems, such as cylinder blocks, valves, pistons, turbochargers, etc. They can also observe hard to see parts such as the chassis, exhaust, and braking systems, improving maintenance efficiency.

Flexible probe: capable of freely bending in complex structures, facilitating in-depth inspection.

High definition imaging: Provides high-quality images for accurate identification of fault points.

Real time measurement function: supports precise measurement of key component dimensions.

3. Pipeline and system inspection

In various pipeline systems, endoscopes pass through the interior of pipelines to detect issues such as corrosion, blockage, and leakage, ensuring the stable operation of the pipeline system.

Wear resistant probe: suitable for long-term use to reduce wear and tear.

Waterproof and oil resistant design: suitable for operation in harsh environments.

Remote control capability: supports remote operation, improves work efficiency.

4. Aerospace field

Used to inspect key components of aircraft engines, such as combustion chambers and turbine blades, and to detect pipelines and wiring inside the cabin. In aircraft maintenance, endoscopes can quickly locate potential faults and improve maintenance efficiency.

High precision measurement: accuracy up to ± 0.01mm, error ≤ 5%, ensuring the safety of critical components.

High temperature resistance and electromagnetic interference resistance: suitable for testing needs in extreme environments.

Lightweight design: easy to carry and operate

5. Energy industry

In power plants and transmission facilities, industrial endoscopes are used to detect the internal structure of generator sets, transformers, and transmission lines, as well as the status of insulation parts. They can also be used to inspect pipelines, valves, and sensors in thermal power plants and nuclear power plants.

Long distance probe: suitable for internal inspection of large equipment.

Radiation resistance: Suitable for special environments such as nuclear power plants.

Real time data transmission: supports on-site data analysis and recording.

6. Chemical and petroleum industries

Applied to corrosion and leakage inspection of chemical reactors, storage tanks, and pipeline systems, and playing an important role in the maintenance of petroleum drilling equipment, it helps to reduce safety risks.

Explosion proof design: Ensure safe use in flammable and explosive environments.

Corrosion resistant material: suitable for strong corrosive environments such as acid and alkali.

Multi functional integration: supports multiple detection modes to improve efficiency.

2025071804.png

7. Food processing industry

Industrial endoscopes can detect the cleanliness and internal structure of food processing equipment, ensuring that the equipment meets hygiene standards and promptly eliminating the risks of damage and contamination.

Explosion proof design: Ensure safe use in flammable and explosive environments.

Corrosion resistant material: suitable for strong corrosive environments such as acid and alkali.

Multi functional integration: supports multiple detection modes to improve efficiency.

8. Underwater engineering

In underwater environments, industrial endoscopes can be used for inspecting ships, marine platforms, and underwater facilities, including hulls, propulsion systems, cabins, and other critical parts.

Large waterproof depth: suitable for detection needs in deep-sea environments.

High voltage resistant design: ensures normal operation in high-pressure environments.

High definition video transmission: supports real-time monitoring and recording

9. Other supplementary applications

Furniture industry: used to inspect the internal structure of furniture such as sofas and beds to ensure quality.

Security check field: Airports, stations, etc. use endoscopes to inspect the interior of luggage, improving the level of security protection.

summarize

Industrial endoscopes play an irreplaceable role in various industrial inspections and maintenance, with a wide range of applications covering aerospace, automotive manufacturing, energy and chemical industries, food processing, and underwater engineering. It not only helps enterprises detect problems in a timely manner, reduce the risk of malfunctions, but also improves safety and production efficiency.

Introduction to the advantages of Coantec Ltd. products

Coantec Ltd. has been deeply involved in the field of industrial endoscopes for many years. The 3D measurement industrial borescope launched by Coantec Ltd. adopts structured light scanning technology and has the following highlights:

High precision measurement: With an accuracy of up to 0.01mm and an error of ≤ 5%, it provides reliable basis for the detection of key components.

Multi functional application: supports multiple measurement modes such as point-to-point, point-to-point, point-to-point, and area measurement, adapting to complex detection needs.

Industry wide adaptation: widely used in aerospace, automotive manufacturing, energy, shipbuilding, and precision machining fields, providing customers with one-stop testing solutions.