Loading

In the routine maintenance of aircraft engines, industrial videoscopes—often referred to as borescopes—are indispensable diagnostic tools. They allow non-invasive visual inspection of critical internal components such as turbine blades, combustor chambers, and compressor sections, significantly reducing the need for engine disassembly. This capability is vital for ensuring flight safety, minimizing aircraft downtime, and improving maintenance efficiency.

However, given the extreme operating conditions and stringent inspection standards in aviation, can general-purpose industrial videoscopes meet these demanding requirements? The answer is a definitive no.

An aircraft engine borescope inspection is far more than a simple "visual check"—it requires the capability to see clearly, measure accurately, and diagnose correctly. This imposes extremely high demands on the equipment’s optical system, measurement precision, image processing capability, and intelligent assistance functions. For instance, the system must not only detect the presence of cracks on blades, but also precisely measure their depth, area, and orientation, and ideally, intelligently classify defect types and generate structured analysis reports. Conventional industrial videoscopes are unable to meet this comprehensive set of stringent requirements.

True aircraft engine borescopes, such as Coantec's X5 series, represent the cutting edge of current remote visual inspection (RVI) technology. Taking the latest-generation X55 as an example, it offers the following key advantages:

1. High-Precision 3D Measurement System

· 3D measurement accuracy: 0.01 mm

· 3D measurement error: ≤5%

· Intelligent 3D measurement: Real-time acquisition of high-density point cloud data, generating clear 3D point cloud images to support precise defect detection and analysis.

· Multi-dimensional accurate measurement: Capable of measuring point-to-point, point-to-line, line-to-plane distances, multi-segment lengths, surface areas, missing corners, cross-sections, and more—delivering stable, reliable data adaptable to complex inspection scenarios.

· AI-Enhanced Algorithms: Integrates high-performance image processing with AI technology to enhance image quality and measurement accuracy in challenging environments.

2. Insertion Tube Replacement Technology

· Modular Design: The main unit supports a variety of insertion tubes with different lengths, diameters, and illumination methods.

· Electrical Quick-Change System: Featuring an innovative patented technology that enables rapid detachment and attachment of the insertion tube to the main unit, significantly reducing operational costs and downtime.

· High Compatibility: Supports a wide range of tube specifications from 0.95 mm to 8 mm in diameter. For tubes 4 mm and above, interchangeable lenses are supported, enhancing versatility and adaptability to various inspection needs

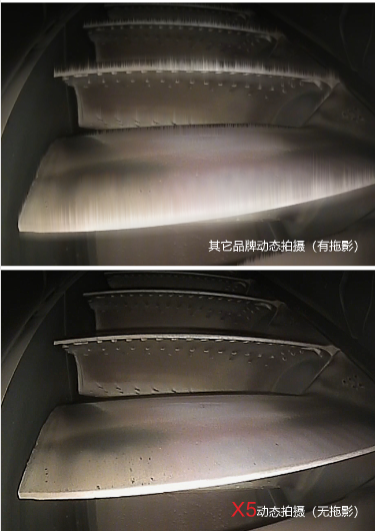

3. Ultra-High-Definition, Lossless Image Quality

Hardware Configuration:

· 3.0 Megapixel Ultra-HD Camera

· 7-inch IPS Full-Lamination HD Touchscreen Display

· High-Sensitivity Image Sensor

Image Processing:

Equipped with advanced high-performance image processing algorithms, the system delivers exceptionally clear and detailed imagery, enabling precise visualization of fine internal defects such as micro-cracks, pitting, and surface irregularities. The combination of superior optics and intelligent signal processing ensures true-to-life, lossless image reproduction in real time, even in low-contrast or challenging lighting conditions.

4. Premium User Experience Design

· Ergonomic Design:

Integrated handheld structure for comfortable, fatigue-reducing operation during extended use.

· Flexible Control:

360° electric joystick enables precise, full-range steering of the articulating tip.

· Structural Innovations:

Dual-threaded lens connection for enhanced durability and sealing

Detachable touchscreen module for improved usability and maintenance

Quick-release handle with removable battery for easy replacement and charging

· Power & Storage:

Dual-power system ensures extended operational time

Built-in 16 GB storage, expandable up to 128 GB via microSD card

Durable Construction: Housing made from ABS+PC high-strength, wear-resistant composite material for reliable performance in harsh industrial environments.

5. Modular and Flexible Configuration

· Interchangeable Optics & Insertion Tubes:

Variety of lens options: straight-view, side-view, macro, near-focus, wide-angle, mid-range, and telephoto

Standard white LED illumination, with optional infrared (night vision), UV, and laser lighting configurations

· Adaptability:

Full range of replaceable insertion tubes from 0.95 mm to 8 mm in diameter, enabling optimal setup for diverse inspection scenarios—from narrow aerospace channels to large industrial ducts.

This modular architecture maximizes versatility, reduces total cost of ownership, and allows users to rapidly reconfigure the system for different applications.